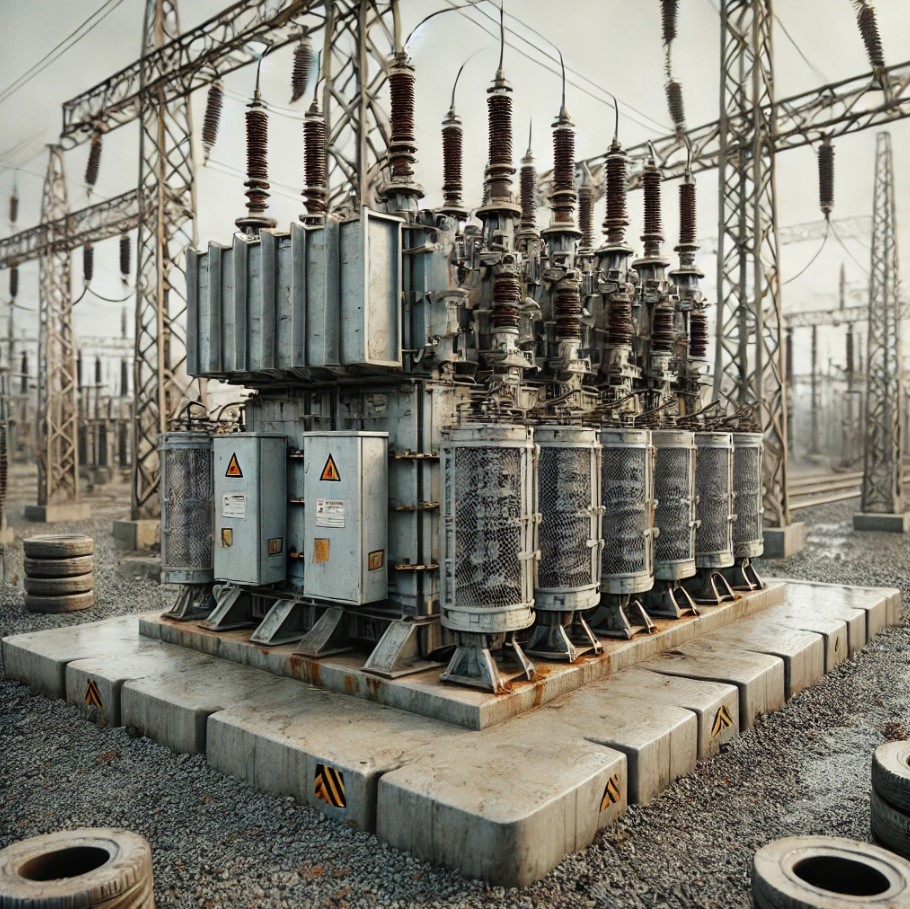

Transformer fire barriers are important for protecting electrical systems from fire hazards. These barriers must be designed to handle environmental challenges like extreme temperatures, humidity, and weather conditions. Selecting suitable materials and construction methods helps the barriers stay reliable in different environments. Focusing on fire barrier construction improves their ability to safeguard critical infrastructure from potential risks. Tailoring them to specific environmental factors ensures they maintain their durability and effectiveness over time.

Adapting Fire Barriers to Temperature Extremes

Materials Suitable for High Temperatures

When transformer fire barriers are exposed to high temperatures, using the right materials is important to ensure they stay effective. Materials such as fire-rated concrete, ceramic fibers, and fire-resistant coatings can withstand extreme heat. These materials are commonly used in regions that experience prolonged periods of hot weather, such as deserts or industrial areas where heat exposure is constant. High-temperature-resistant barriers not only prevent fires from spreading but also help to maintain the structure’s integrity, keeping the transformer and surrounding equipment safe.

Handling Low-Temperature Conditions

Fire barriers must also be capable of performing in cold environments where materials can become brittle. In areas like Alaska or regions with long winters, materials such as intumescent coatings and special fire-resistant polymers work well in freezing conditions. These materials help prevent the barrier from cracking or losing its protective properties due to temperature shifts. Cold-resistant materials ensure the fire barriers remain durable and effective, even when temperatures drop significantly, maintaining safety standards and preventing potential fire hazards during cold weather.

Protecting Against Moisture and Humidity

Water-Resistant Fire Barrier Materials

In areas with high moisture or constant rainfall, using water-resistant fire barrier materials is important to maintain effectiveness. Materials, like treated gypsum boards, fiberglass, and fire-rated cement boards, are often used in these conditions. These materials are specifically designed to resist water infiltration, preventing the fire barrier from weakening or failing over time. Coastal regions or areas that experience frequent heavy rain, like the Pacific Northwest, require barriers that can withstand moisture exposure without compromising their protective abilities. By using water-resistant materials, fire barriers remain strong and functional in wet environments.

Preventing Corrosion in Humid Environments

High humidity can cause corrosion, weakening the materials used in fire barriers and making them less effective. In locations with a tropical or humid climate, like Florida, choosing materials resistant to corrosion is essential for long-term protection. Metals like stainless steel and galvanized steel are ideal for these conditions. These materials resist rust and deterioration, ensuring that the fire barriers maintain their structural integrity. Regular maintenance and the use of protective coatings can further reduce the risk of corrosion, helping the fire barriers continue providing reliable protection in humid environments.

Addressing Wind and Airflow Challenges

Reinforcing Fire Barriers for High Winds

In areas prone to strong winds, fire barriers must be reinforced to handle the pressure and prevent damage. Materials like reinforced concrete and steel structures are often used in locations that experience hurricanes or high wind speeds, such as coastal regions in the southeastern United States. These materials provide extra strength, preventing the fire barriers from being compromised by the wind. Ensuring proper installation and securing the barriers to the foundation can further enhance their resistance, making them more reliable in windy conditions.

Improving Airflow Without Compromising Protection

In some environments, maintaining airflow around fire barriers is important for equipment cooling while still providing fire protection. This is especially relevant in industrial settings where transformers need airflow to operate efficiently. Using fire-rated vents or specially designed barriers that allow controlled airflow can help in these situations. These vents are constructed to close automatically if fire or smoke is detected, ensuring protection without hindering ventilation. Locations such as power plants can benefit from these designs, balancing airflow and safety without sacrificing protection.

Managing Seismic Activity and Structural Shifts

Flexible Fire Barriers for Earthquake-Prone Areas

In earthquake-prone regions, fire barriers must be designed to handle seismic shifts without losing their effectiveness. Materials like flexible fire-resistant coatings and fire-rated expansion joints are commonly used in areas such as California or Japan. These materials allow the barriers to bend and move with the structure during an earthquake, keeping their protective abilities intact. Flexible fire barriers help reduce fire risks even when structural shifts occur. This is especially important in protecting critical infrastructure, such as power plants and transformers, where safety is a top priority.

Securing Fire Barriers During Structural Movement

During structural movement caused by seismic activity, securing fire barriers in place is important for maintaining safety. Anchoring methods, such as mechanical fasteners or specialized brackets, are used to hold the barriers securely. In areas near fault lines or regions that often experience tremors, these systems help fire barriers stay stable even when the ground shifts. Regular inspections of these fastening systems are necessary to ensure they remain secure, reducing the chance of fire hazards during seismic events.

Mitigating Chemical Exposure Risks

Resistant Materials for Chemical-Heavy Environments

In environments where chemicals are frequently used, selecting fire barrier materials that can withstand exposure to corrosive substances is important. Fire-resistant materials like stainless steel, fiberglass-reinforced plastic (FRP), and chemical-resistant coatings are commonly employed in chemical plants or laboratories. These materials are chosen for their ability to resist damage from acids, solvents, and other harsh chemicals, ensuring the fire barrier remains effective. Locations such as industrial facilities often use these materials to prevent chemical reactions that might weaken the barrier, providing a stronger level of protection against fire.

Maintaining Fire Barrier Integrity in Hazardous Locations

In hazardous locations where chemical spills or leaks are common, maintaining the integrity of fire barriers is crucial. Regular inspections and repairs are needed to prevent deterioration from chemical exposure. Areas like refineries or chemical processing plants often face such risks, so fire barriers are built using materials that can handle ongoing exposure to chemicals. By performing routine checks and applying protective coatings when necessary, fire barriers can remain strong, helping reduce the risk of fire spreading in environments where hazardous materials are present.

Meeting Environmental Regulations

Compliance with Local Environmental Laws

Fire barrier installations must comply with local environmental laws to avoid penalties and ensure safety standards are met. Each region has specific regulations regarding fire safety and environmental impact, which must be followed carefully. For example, California has strict guidelines on fire prevention and environmental protection due to its wildfire risk. In industrial areas, fire barriers must also comply with pollution control standards. Adhering to these local laws ensures that fire barriers are both safe and environmentally responsible, reducing legal risks for businesses.

Choosing Eco-Friendly Fire Barrier Solutions

Many industries are now prioritizing eco-friendly fire barrier solutions to reduce environmental impact. Materials such as recycled steel, low-toxicity fireproofing, and sustainable coatings are becoming more common. These materials not only meet fire safety standards but also contribute to a greener, more sustainable future. In regions with strong environmental protection laws, such as the European Union, using eco-friendly solutions helps companies align with environmental goals while maintaining fire safety. By choosing materials that minimize harm to the environment, businesses can support sustainability without compromising protection.

Maximizing Transformer Fire Barrier Performance

Transformer fire barriers need to be optimized for various environmental conditions to ensure safety and reliability. Selecting the right materials and construction techniques makes these barriers more effective in challenging environments. Each condition presents its own set of challenges, which can be addressed by choosing adaptable solutions that meet safety standards. Investing in properly constructed fire barriers helps safeguard critical systems in all types of environmental conditions.